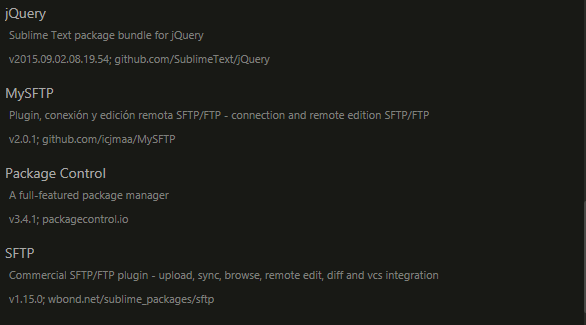

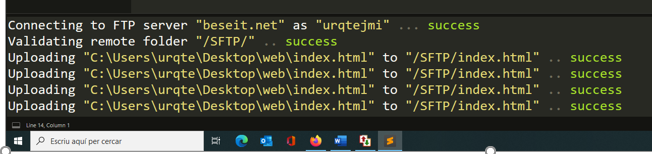

Aquesta configuració ha funcionat

{

// The tab key will cycle through the settings when first created

// Visit https://codexns.io/products/sftp_for_subime/settings for help

// sftp, ftp or ftps

"type": "ftp",

"save_before_upload": true,

"upload_on_save": true,

"sync_down_on_open": false,

"sync_skip_deletes": false,

"sync_same_age": true,

"confirm_downloads": false,

"confirm_sync": true,

"confirm_overwrite_newer": false,

"host": "beseit.net",

"user": "urqtejmi",

"password": "Beseit1968!",

// "port": "21",

"remote_path": "/SFTP/",

"ignore_regexes": [

"\\.sublime-(project|workspace)", "sftp-config(-alt\\d?)?\\.json",

"sftp-settings\\.json", "/venv/", "\\.svn/", "\\.hg/", "\\.git/",

"\\.bzr", "_darcs", "CVS", "\\.DS_Store", "Thumbs\\.db", "desktop\\.ini"

],

//"file_permissions": "664",

//"dir_permissions": "775",

//"extra_list_connections": 0,

"connect_timeout": 30,

//"keepalive": 120,

//"ftp_passive_mode": true,

//"ftp_obey_passive_host": false,

//"ssh_key_file": "~/.ssh/id_rsa",

//"sftp_flags": ["-F", "/path/to/ssh_config"],

//"preserve_modification_times": false,

//"remote_time_offset_in_hours": 0,

"remote_encoding": "utf-8",

//"remote_locale": "C",

"allow_config_upload": true,

}